If you’re going to operate an overhead crane, also called a gantry crane, there are certain types of training that you need to have in order to be proficient. You need to be aware of the different controls that you are responsible for lifting, lowering, and moving the items that have been attached to the chain or cable at the bottom of the hoist. This can take quite a bit of time to master, depending upon the size and capability of the overhead crane that you are responsible for. Here is a general overview of how these cranes work, and the different controls that you will more than likely need to learn how to master to operate this device.

How An Overhead Crane Works

A gantry crane is installed either indoors or outdoors. It will have supporting beams, runway beams, and bridge girders that will be perpendicular to the runway beams that provide its support. Upon the bridge girder, which could be either single or double, you will have the trolley frame upon which the hoist will be connected. This will allow you to move the overhead crane back and forth, and the trolley frame side to side. You will also be able to control the hoist which will go up and down, allowing you to virtually move any object below to a different location. For safe operation, It is helpful to learning more information about different types of cranes.

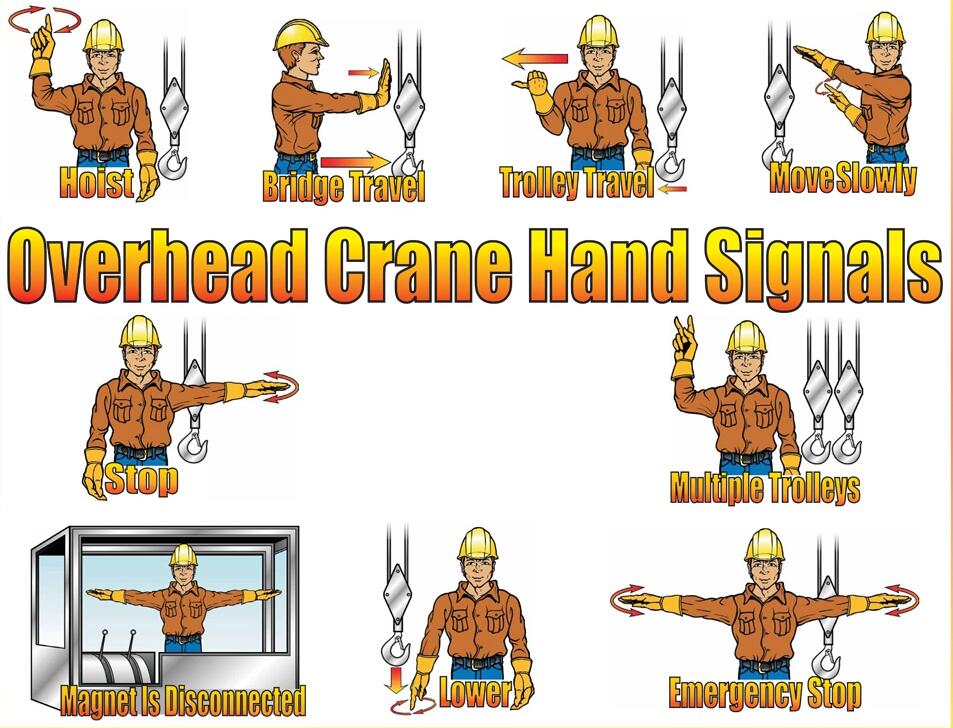

Understanding The Controls

The controls that you will use will be very minimal, but will take your maximum attention. There will likely be buttons that will turn the control panel on or off which will activate the gantry crane. You will also have a joystick that you will control for operating the hoist, the trolley frame, and also the bridge girders on the runway beam. This will give you the ability to move it within the confines of its limitations per its construction either indoors or outdoors. Although there may be more delicate controls that can be used for very detailed movements, this is the basic control panel that you will be operating to control all four of these functions.

How Long Will It Take To Master?

It should only take a few weeks for you to become masterful with the controls, especially if you are being tutored or trained by someone who has done this before. It is possible to watch videos on how to run the exact unit that you will be operating, although it is better to have one-on-one tutorials provided in person. Additionally, you will never be able to control it properly unless you are using it in an actual business setting. Once you are used to the routines of the business, and also how the controls are manipulated, you will then be able to master that particular machine for your company to maintain production levels.

This basic overview of how to properly operate an overhead crane should give you a general idea of what to expect. They are all made in a similar way, and the control panels are also very similar, so it should not be too much of a problem to either learn everything up front, or transition to a completely different overhead Crane operation.

millimeters while other produce between 80-90 kg/square millimeters of bending force. The capacity can also be illustrated by the amount of horsepower the machine has. The higher the horsepower a machine can produce, the faster it can bend bars and thus the more expensive it will be. Finally, the capacity of the machine can also be illustrated by the bar gauge numbers the machine can bend. The higher the variety gauges the machines can bend, the higher it will cost.

millimeters while other produce between 80-90 kg/square millimeters of bending force. The capacity can also be illustrated by the amount of horsepower the machine has. The higher the horsepower a machine can produce, the faster it can bend bars and thus the more expensive it will be. Finally, the capacity of the machine can also be illustrated by the bar gauge numbers the machine can bend. The higher the variety gauges the machines can bend, the higher it will cost. Energy Efficiency

Energy Efficiency

They Make A Great Photo Op

They Make A Great Photo Op While most rides and attractions are completely safe, some of them can feel dangerous. Thankfully, that’s not the case with kiddie trackless trains in Beston. They’re 100% safe, and nothing about them feels risky.

While most rides and attractions are completely safe, some of them can feel dangerous. Thankfully, that’s not the case with kiddie trackless trains in Beston. They’re 100% safe, and nothing about them feels risky. They’re Affordable

They’re Affordable

If you need to be sure that you are getting all that you can from your amusement park ride, be sure that you keep up with the maintenance. This will allow you to keep the ride safe and sound so that you are not injuring people at the same time. With this in the back of your head, you will be able to get the assistance required for helping you find the highest quality ride. Make the most of this by getting high quality contractors to service the ride for you.

If you need to be sure that you are getting all that you can from your amusement park ride, be sure that you keep up with the maintenance. This will allow you to keep the ride safe and sound so that you are not injuring people at the same time. With this in the back of your head, you will be able to get the assistance required for helping you find the highest quality ride. Make the most of this by getting high quality contractors to service the ride for you.

For those wishing to derive an income from operating a miniature railroad the ease with which the tracks and the locomotive and associated stock can be transported as well as set up makes them a popular choice for entrepreneurs. These miniature railways can be found in malls and fairgrounds, as well as operating at private functions across the country on a regular basis.

For those wishing to derive an income from operating a miniature railroad the ease with which the tracks and the locomotive and associated stock can be transported as well as set up makes them a popular choice for entrepreneurs. These miniature railways can be found in malls and fairgrounds, as well as operating at private functions across the country on a regular basis.

It is always a good idea to do a little planning before you go to a fair, carnival, or amusement park. After all, there is little reason to go if there are no suitable rides for your children. Imagine how disappointed they might be if you arrive at the park, only to find out that they are too young to go on any of the rides.

It is always a good idea to do a little planning before you go to a fair, carnival, or amusement park. After all, there is little reason to go if there are no suitable rides for your children. Imagine how disappointed they might be if you arrive at the park, only to find out that they are too young to go on any of the rides. You should definitely find a company that will also set up the cars and show you how to use them. Just having them dropped off at your home is not enough. You need to choose a company that will work with you to help you answer your questions and address any concerns that you may have. You can click this page:

You should definitely find a company that will also set up the cars and show you how to use them. Just having them dropped off at your home is not enough. You need to choose a company that will work with you to help you answer your questions and address any concerns that you may have. You can click this page: