Obtaining a reliable asphalt mixing plant does not have to be a difficult process. There are many different ones that are available, some of which may be better suited for the type of work that you are in. Some are portable allowing you to bring them with you to different job sites. Others are going to be quite large, capable of producing more than enough for you and other businesses. The one that you purchase will depend upon your intentions, how much production you are looking at, and the number of jobs that you do on a monthly basis. There are also differences between the many different types of asphalt batch mix plant philippines that are currently being sold. This overview will show you which ones might be best suited for the type of work that you do regularly.

Different Types Of Asphalt Mixing Plants

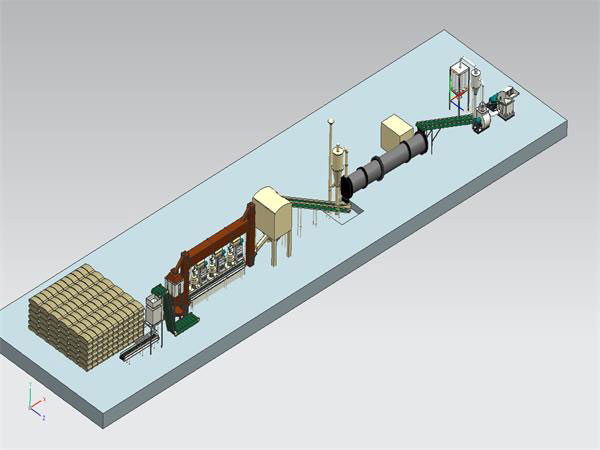

Some of the asphalt mixing plants that you will find online are extremely large. They can be used for businesses that are consistently doing work on highways, roads, airports, and even at harbors. You are able to monitor how much is made, and also modify the consistency of the asphalt that you are producing. The best asphalt mixing plants may not be the most expensive. It depends upon where you are looking for them, and how long you are willing to wait in order to receive all of the different components. They are often differentiated based upon the many components that come with each one.

Features On Different Asphalt Mixing Plants

There are several features that you will need to consider before making your final purchase. They should have an automatic diagnostic system, frequency control capabilities, and a programmable console. They may also have protection system set up in case something goes wrong, and they will also have secondary metering devices. All of this will be assessed as you are looking at both stationary and mobile units plant.

Where To Find The Best Ones Currently Being Sold

The best ones that are sold today can be obtained from countries such as Europe, China, and even Indonesia. Some of the largest producers are in the Orient. They will have a multitude to choose from, and they will allow you to get a quote by requesting one on their website. You can find their websites by visiting international classified sites that are allowing them to advertise. By comparing the different features and advantages of each one, you can decide on which one will be the most appealing. Likewise, you will also see the prices that they will cost after you have requested quotes from each company. This may be the deciding factor when selecting one of these units. Continue to get more information: https://twitter.com/AimixG.

Whether you are focused on obtaining a portable unit, or the largest asphalt mixing plant available, all of this can be found very quickly online. This information will be presented on advertising websites, as well as on the main sites for different manufacturers. Choosing a quality asphalt mixing plant is always the goal, but there are so many differences to consider. That’s why doing research is so important, comparing the advantages and features that each one offers, and eventually choosing one that will be right for your business.