Since tyre and plastic and rubber are non-biodegradable, they are very lethal to the environment. One-third of all the waste produced in the world today is tyre and plastic – a very serious environmental hazard indeed. The good news is that we can recycle tyre and plastic and rubber by continuous tyre pyrolysis plant, thereby reducing pollution of our water bodies and saving our plants and animals.

Our continuous pyrolysis plant is used all over the world to recycle waste plastic, tyres and other forms of rubber into oil which can be used as fuel. The pyrolysis process also produces valuable gas, steel and carbon black powder. Carbon black is used in many industrial processes to strengthen and improve the endurance of various materials.

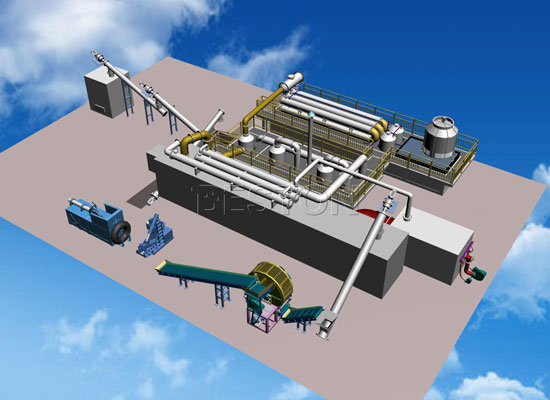

Continuous pyrolysis plant

The continuous waste tyre recycling machine has various great features such as automatic feeding, mixing and production, clean energy heating mode, high thermal efficiency, closed clean production, automatic pressure operation and a high cooling speed. It has a long life, is easy to operate and maintain and does not take a lot of space. The oil and the carbon produced are of a very quality because the machine is designed to the highest standards of manufacturing excellence. Get the tyre to oil plant cost from reliable manufacturer – Beston.

The waste tyre and plastics are shredded and continuously fed into the reactor via the feeding machine. The materials are then pre-heated during the conveying process and since tyre has a low melting point, it is converted into pyrolyst which is then neutralized and treated after it is separated from other materials.

Beston Continuous Tyre Pyrolysis Equipment for Sale

The constant temperature of the continuous pyrolysis equipment’s heating system supplies heat to the reactor. This makes it possible for the raw materials to be continuously fed into the reactor without stopping the machine for feeding or for emptying. The process of pyrolysis is enhanced by a high-efficiency catalyst. The small amount of residue produced from the reaction can be further processed into fuel sticks. Besides the continuous equipment with large capacities, we also have small pyrolysis machine for sale.

The continuous pyrolysis equipment manufacture by Beston Machinery Co., Ltd. has various subsystems which include the gas purification system, constant temperature heating system, waste tyre pre-treatment system, combustible gas scrubbing system and the HCI absorbing system.

Waste recycling has empowered many communities around the world especially in countries which don’t have a policy on the disposal of tyre and rubber. You too can become a successful industrialist simply by processing waste tyre and rubber. Talk to us today to see how we can help you achieve your dream.