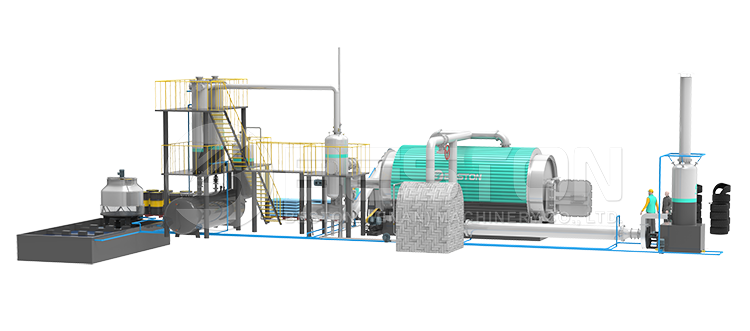

The waste oil distillation machine is an appliance which uses green technology in the process of distillation of waste oil or crude oil. In fact, the principle of pyrolysis technology is used for getting the fuel from waste tires. With the distillation machine, the crude oil is refined into the diesel oil. This will solve the oil resources as it will decrease the problem of waste disposal. See the portable pyrolysis machine here.

Pyrolysis Plant Design

Properties of waste oil refining equipment

The waste oil distillation equipment features the following properties:

· It operates at constant pressure.

· Its raw material is waste engine oil, plastic crude oil and waste tire crude oil.

· The structural form of the distillation machine is very easy to clean and maintain.

· The heating method is indirect and it prolongs the equipment’s service life operating at constant pressure.

· The final oil product can be used directly in trucks, vans and diesel generators. Also, you can use it to heat your plant to save your waste tyre pyrolysis plant cost.

· It has three steps of the purification process so as to ensure that the final product is pure and it is of high quality.

· The service life can be increased through indirect heating of the boiler system.

Pyrolysis Plant in UK

Advantages of waste oil distillation equipment

#1. Used for security operations

· Enables all the welding to be detected by the ultrasonic non-destructive testing methods so as to ensure that both the welding shape and quality is achieved.

· The waste oil distillation plant is equipped with anti-explosive equipments, safety valves, temperature meters, pressure valves, alarming systems and temperature meters.

· The machine has adopted automatic submerged welding technology.

#2. Low cost in terms of operation and energy conservation

The special covers which the appliance has can keep hot during heating. Also, the direct heating system and the good heating efficiency will save both energy and cost.

· It is relatively cheap.

An individual will be able to use only 30 dollars for treatment of one ton of used oil.

· Easier operation.

The machine can be operated by only one to two individuals

· It has a variety of usage.

This type of machine is able to treat diesel oil, gasoline oil, rubber oil, as well as waste tube oil of an engine.

· One can get high quality base oil.

With no unsaturated composition, the oil can be stored for a long time with the color and smell not getting bad.

The impact on the environment of the waste oil distillation equipment

The waste oil distillation machine is environment friendly. This is because of the following features:

· The emission standards : The device adopts special gas scrubbers which removes dust and acid gas from the smoke.

· The water pollution : There is no water pollution.

· The smell during the operation: It is fully enclosed during the operation. Hence, there is no smell.

· The solid pollution: after pyrolysis, the components are steel wires and crude oil which can be either solid directly or deep processed with its valves.

Application of waste oil distillation equipment

The waste oil distillation machine is mainly used for purification of the: waste engine oil, pyrolysis oil and the diesel engine. The device can be utilized in: diesel engine oil generators, tractors, ships and trucks. See the high quality pyrolysis plant for sale here.