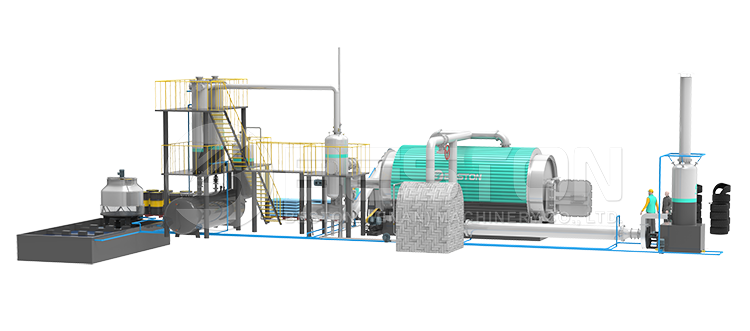

Car tyres are not forever. Everyone needs to change them every few years or so. This generates a huge amount of waste tyre that can be turned into something useful. If you want to start a tyre recycling business, you’ll need to buy a pyrolysis plant. Let’s see where you can find some reliable suppliers of such equipment.

Tyre Pyrolysis Plant in the UK

The good news is that all the suppliers you need are inline, waiting for you to find them. However, you’ll need to undergo some research to weed out the unreliable ones. This is going to take a little time, but it isn’t rocket science, so you shouldn’t have any problem in choosing a trustworthy company to buy your machine from.

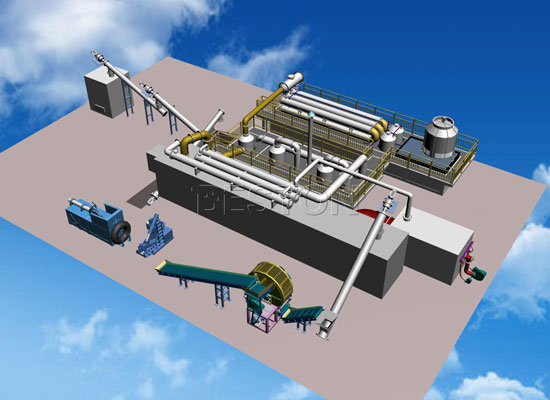

Start by performing a search in Google or in any other search engine you may want. Since waste tyre pyrolysis plants aren’t cheap, you should seek directly for manufacturers, in order to avoid paying feeds to the middleman. If you want to find reasonably priced equipment, you should be ready to seek for suppliers in China. All these countries are much cheaper, so you’ll find good quality equipment at lower prices than in America. If you do your homework properly, you shouldn’t encounter any problems, as many of these suppliers are keen on providing high-quality products to their clients. If you focus on China manufacturers, such as Beston Group, the best thing about this marketplace is that it enables users to rate and review the services and products they’ve purchased via the directory. This means you’re going to know at first glance which seller you can trust to provide you with the best tyre to oil plant.

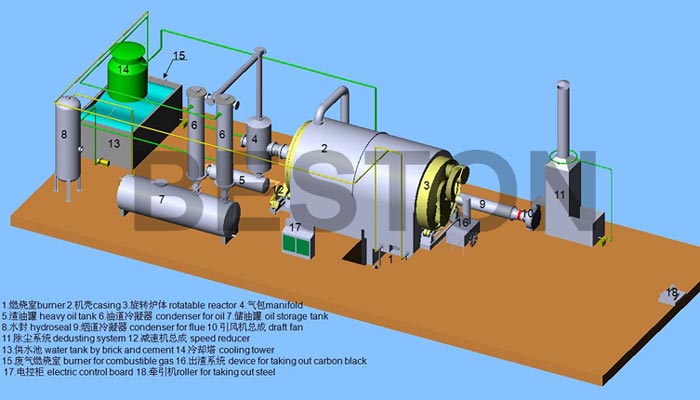

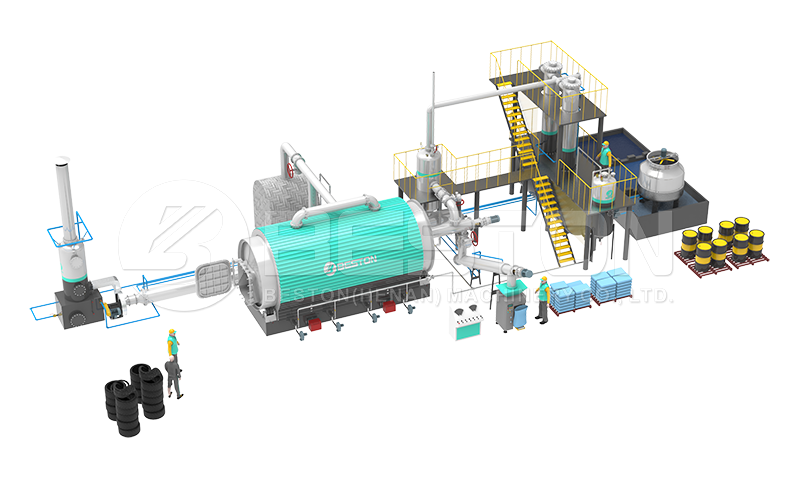

Tyre to Oil Plant Design

For each of your potential suppliers, you have to check for how long they’ve been in this industry, and how reputable they are. Ideally, you should be able to find some client feedback online, either on their business pages or in discussion groups and online communities that tackle such recycling topics. If you fail to find any customer reviews, you can contact these manufacturers to ask for client references. This is good method to check how reliable these companies are. If their other clients are happy with the quality of the products and post-sales services received, chances are you’re also going to be satisfied. If, on the contrary, their clients say they had various problems, you may want to avoid that supplier and seek for a better one. Beston also supplies the customized tyre recycling plant business plan.

As you can see, online directories and business pages can be a great source of reliable suppliers of any type of equipment you want. Also, you can get the cost of tyre pyrolysis plant. However, you should be careful when you make your choice, so that you can get the best value for your money. Always check the background and the references of each provider, and try to get quotes from at least three suppliers. This is a surefire recipe for success. See the mini pyrolysis plant here.